Review: 2010 Beretta A400 Xplor Unico 12 Gauge Autoloader

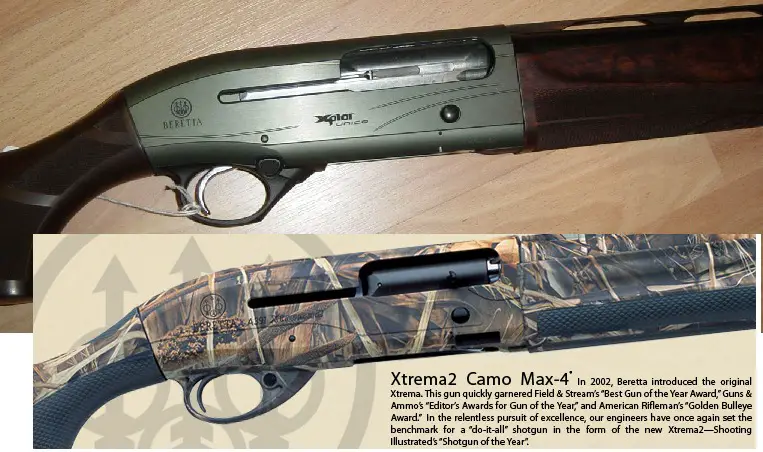

With over a dozen lines of autoloading shotguns in countless variations, Beretta Group offers more autoloading shotguns than all of its major competitors combined. The A400 Xplor Unico, shown above with the Kick-Off buttstock option, is the latest addition to this increasingly well-populated field.

Under the sprawling umbrella of the Beretta Group, we have what may be the largest assembly of autoloading shotguns ever assembled by one gun company in history. With the addition of the A400, we have four gas actions from the Beretta brand alone: the 390 / 3901, the 391, and the 391 Xtrema models. We have a fifth autoloader, the two shot Beretta UGB25 Xcel, that uses a short recoil action.

Under Beretta's Franchi brand, we have the long-recoil AL48, the gas-operated Franchi 720, and the recoil-inertia I-12. With Beretta's Stoeger brand, we have the Model 2000 inertia autoloader. With Benelli, we have the gas-operated “A.R.G.O” M-4, the inertia Super Black Eagle, the M-2 series, and several variants, and the inline modular inertia Vinci. That's quite a stable of autoloading shotguns, considering Browning fields only two gas guns, with Remington down to essentially one offering. You almost need a scorecard to track the lineage of the new A400 Unico. The basic action is found in the 1998-introduced Franchi 612 / 620 Variosystem-Variomax gas autoloaders. The gas-operated Franchi Model 912 Variomax 3.5 was considered a new model in 2001, still with a rotary bolt but now with 2-3/4, 3, and 3-1/2 inch capability. The 912 required a minor adjustment to go from target loads to heavy loads, an adjustment not required with the Xtrema2.

The approximately 7-3/4 lb. Xtrema2 can generally use loads from peppy 1 oz. payloads on up to the heaviest 3-1/2 inch shells without adjustments. The A400 Unico seeks to go a notch wider in the load spectrum, billed as ideal for loads from 7/8 oz. to 2-1/4 oz. in its 3.5 inch chamber without adjustment while knocking off a full pound of weight from the Xtrema2: the A400 is presented as a 3 kg (approx. 6.6 lb.) shotgun. It isn't, really, but that is the claim.

In the grand scheme of things, Beretta is rather inexperienced in the autoloading shotgun market. The first Beretta autoloader to have much impact (at least in the U.S.) was the Model 303, introduced in 1987. For eighty-five years prior to that, the autoloading market was dominated by Browning initially, then Browning and Remington from the 1950s onward. Things change, though, and Browning's B2000 gas gun wasn't much of a success, providing the motivation for the 1981-1988 Browning B-80, a variation of the Beretta 302 autoloader that was made by Beretta for Browning. Beretta's traction gain in the United States coincided with the dissolution of the Beretta-Browning partnering and the discontinuation of the B-80 along with it.

It wasn't until 1995 that the “all-load” gas autoloader was introduced (by Beretta) in the form of the model 390 series, a year after the introduction of the Browning Gold. Though shooting a variety of shells with no adjustments is now considered standard fare, that wasn't the case at all in a popular sense until the mid to late 1990s. Prior to that it was either change barrels (B2000, A300 series) or change settings. It only took ninety years or so for Browning and Beretta to figure it out. Other companies never have.

From a practical perspective, the notion of 7/8 oz. to 2-1/4 oz. payloads in the same gun is a matter of trivia. No one I know wants to shoot 2 ounces of stuff at a bird, much less 2-1/4 ounces. 1-7/8 ounce three inch shells are available in three inch hulls, though outside of turkey there is little use for them. With the advent of better shot materials than lead, there is scant reason to go beyond 1-5/8 oz. (as in Federal Heavyweight #7 loads) and even then it is a single shot application where a gas-operated autoloader offers no value beyond recoil reduction. Recoil that no one feels in most cases. Heavy 3-1/2 inch steel loads have 1-1/2 ounce payloads with far more effective shells available in three inch unfolded lengths with higher density shot materials, rendering both 3-1/2 inch chambers and 2-1/4 inch payloads a “feature,” but hardly one containing a great deal of sense.

Part of this is more intellectual collision than anything else. When you take a bulky, 3-1/2 inch action that wasn't needed or desired in the first place, then brag how you were able to shrink it closer to 3 inch action envelope questions, it begs the question as to why it wasn't a 3 incher all the while? The same is true to an extent with Beretta's “Kick-Off” system. Designing a light, responsive autoloader then attaching a half-pound glob of rubber enclosed shock absorbers to the buttstock to bump it over 7 pounds is working at cross-purposes. Part of this is reflected right back at the individual who still has to define their own needs. You might want to consider that the largesse of Beretta field O/U models, including their six pound Ultralight 12 gauge stackbarrel, is not supplied with any Kick-Off system, though they are in need of it far more than gas guns.

So, the Kick-Off is a fairly old idea. I had a pair of Winchester 1200 pump guns with factory “Hydrocoil” stocks that used the same premise. Aftermarket Gracoil and Ken Rucker's highly regarded Bump-Buster stocks are more advanced solutions along this line. I'm spending a little extra time on the matter as the A400 with KO retails at an impressive $1725. Before you go that route, if recoil is a strong issue, you might want to consider that the heavier Beretta Xtrema2 KO is going to be the softer shooter. Seeking no recoil from light guns with heavy loads is like teaching a pig to dance. It is fruitless and invariably irritates the pig. Though now associated with the A400, the KO has already been available in the Xtrema 3-1/2 in. series and the 391 Urika2 3 inch guns for some time.

The Kick Off hydraulic buttstock has been applied to various models over the last few years, including the Beretta 391 Urika 2 as shown above.

Originally, I shot both the standard A400 alongside the A400 KO with Federal 1-1/8 oz. Gold Medals. There was no noticeable discomfort from either gun. The only thing I noticed was the creepy feeling of pressing part of an old, spare tire against my shoulder with the KO and the extra weight. Not my cup of tea at all. It is no accident that I'm testing and reviewing the sans KO model.

Anodizing aluminum alloy in various colors is not exactly new. One of the most common examples was the Val Browning designed "Double Auto," offering the Twelvette series of the Double Auto with various receiver colors.

Many of the hyped “features” of the A400 are not particularly new, novel, or innovative. Browning Double Autos came a variety of anodized colors in the Twelvette series. The action is called the Blink system, fastest in the world which we can now compare to the Xtrema2 world's fastest action, the Browning Maxus fastest action, the Winchester SX3 fastest action, and the Benelli world's fastest actions. All a bit silly, as no one can possibly outrun an A-5 with aimed fired in the first place. Any number of autoloaders cycle faster than you can.

Naturally, there is a new choke system, the “Optima HP," meaning that all of your other choke tubes aside from the SV10 Prevail O/U won't fit the Unico, so you can go buy new ones. Likely, you'll want to as Beretta skimps a bit by supplying only three choke tubes versus the five or six you might expect on a premium priced gun. The A400 has a MSRP of $1625 as tested, $1725 with the KO.

The A400's KO3 feature. While felt recoil reduction due to this addition is debateable, it does however make a significant advance over little plastic bolt buffers in keeping unwanted impact stress away from the bolt and receiver. Rocket loads are unlikely to peen and batter the receiver with the KO3. I'm of the opinion that it allows for higher bolt speed without any propensity to crack parts.

There is one feature of the Unico action that I feel is particularly noteworthy, though, dubbed the “KO3” or Kick-Off Cubed assembly. To have a reliable gas autoloader, you need adequate bolt speed. The issue with non-compensating actions from the Remington 1100 to the B-80 and 302/303 Beretta series is that the more gas flow you have through the ports, the more the gun tries to bang itself to pieces. Gassy loads through a B-80 or A303 can result in receiver peening, an abrupt pop at the end of breech-bolt travel you can feel and sometimes hear. Tired-out buttstock mainsprings add more shock and vibration. This hasn't been completely cured in the A390, though you can tune a 390 by switching out secondary bleed springs. It also isn't completely cured in the 391 Urika, either, though Beretta has played around with different bolt buffers to address the bang and clang.

The KO3 is a small hydraulic cylinder in the buttstock that the bolt intentionally impacts at the end of its travel, providing shock absorption and cushioning that no plastic bolt buffer can provide. It is a fabulous idea, allowing for aggressive bolt speed and function without smashing the receiver or giving the shooter a quick second pop. It is the KO3 that allows for faster cycling, but importantly more positive cycling throughout the spectrum without inflicting excessive stress to the receiver. Not easily employed on other actions, it is easily implemented on the Unico as all the “gas guts” are inside the forearm, just as they are on the Xtrema2. The old Browning B2000 had all the goodies inside the forearm as well, but lacked a compensating action and still relied on a plastic bolt buffer that was prone to wear. Even the original Winchester Super-X Model One, a superbly made gas auto, was plagued by an overly heavy bolt and liked to eat bolt buffers, even though it was a 2-3/4 in. chambered gun only. This is a substantial advance and Beretta deserves congratulations for it.

The A400 is light and spritely. Most of the weight savings comes from the prolific use of plastic, which is referred to as “techno-polymer.” I'm not sure precisely how the distinction is made, except that techno-polymer most assuredly will cost you more money. The forearm nut is plastic, apparently a take-off internally from the complicated 391 nut, this time with plastic internals. The front of the forearm itself is plastic, as is the trigger guard. The action sleeve is made from soft plastic as well.

Though the A400 is touted as having a super-compact receiver, that might be a bit of a stretch. It remains longer and bulkier than the vintage B-80 shown on the left, a Beretta product once marketed by Browning as shown above.

The tested 28 inch barreled A400 sans Kick-Off, weighs 6 lbs., 13 ounces unloaded as verified by electronic scale, about one half pound heavier than advertised. The receiver, touted as “super-compact” and the same as 3 inch autoloading receivers, really isn't. It is roughly 8-1/2 inches in length compared to my 3 inch A390 receiver with 8 inches of length, my 3 inch steel B-80 receiver is a bit shorter than that. The A400 trigger breaks at about 4-3/4 lbs. with a small amount of creep. I'd consider it better than many autoloaders, particularly the universally heavy-triggered Brownings. The recently reviewed Maxus examples came with 6-pounders. I consider anything better than five pounds on a mass-produced autoloader a bonus.

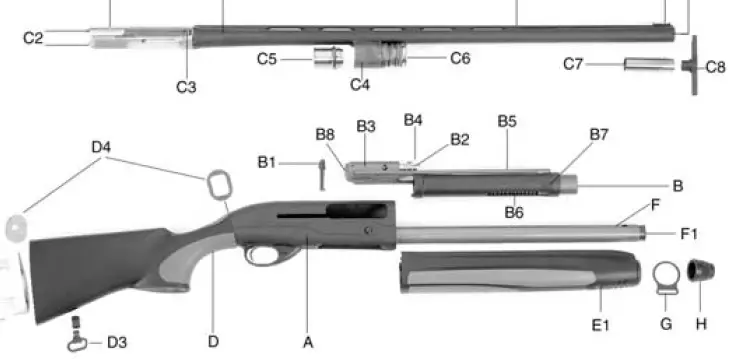

A glance at the A400 Unico and the Xtrema2 along with an exploded view of the Xtrema2 (above) leaves very little doubt as to the primary parent of the A400.

The walnut stock of the A400 is designated as “new X-Tra Grain Technology with oil finishing.” Though it looks greasy, slippery, and inauthentic in Beretta stock photographs, in person it looks far better. It is an effort to spice up plain walnut with a coating that adds character. Less charitable folks call it "fake grain," which is correct. In this case, it generally works. It isn't at all high-grade wood as a peek inside the stock and forearm reveals, but it does have the warmth of wood in feel, and is pleasing to the eyes. The checkering is well executed and functional.

The A400's bore is .730 inches via Skeet's bore gauge. For pattern testing, I used the supplied “Full” factory choke that has an exit diameter of .697 inches for an effective constriction of .033 inches. The A400 essentially shot to point of aim at 40 yards, the patterns well-centered if characteristically high. With B& P USA 1-1/8 oz. F2 Legend #7-1/2 shells, the patterns offered both good density and distribution, better than most factory Full choke tubes.

In the felt recoil department, I tested the A400 against an older technology Beretta, a B-80 12 gauge. The steel B-80 is a heavier gun, a full pound heavier than the A400. Naturally, the B-80 is a different action as well, lacking the Optima HP barrel, extended forcing cone, the Kick-Off3 device, and the Micro-Core pad. The side by side shooting commenced with B & P F2 Legend 1-1/8 oz. loads, continued through Winchester 1-3/8 oz. 1300 fps Super-Pheasant loads, and finished with the flame-throwing Fiocchi 1485 fps 1-3/8 oz. GPX Golden Pheasant loads. Recoil was virtually indistinguishable between the two guns. Both were quite comfortable with the B & P F2 loads, both guns became unpleasant after several rounds of the 1485 fps 1-3/8 oz. Fiocchi loads. All of the shooting was done wearing a thin short-sleeved shirt, no shooting vest, etc., as the idea was to feel recoil not to get comfortable using outerwear adjustments. Again, no tangible difference between the guns. The most noticeable difference is that the A400 emitting a resonating humming sound when using the higher-intensity loads where the B-80 did not.

The A400's action stayed clean, with little residue migrating over the mainspring, action sleeve, or to the bolt. Stripping and cleaning the A400 is easy and straightforward. Two areas that may need attention eventually (how long is speculative) are the overly complicated forearm nut and the gas valve assembly. The owner is cautioned in the manual not to disassemble the gas spring and valve assembly, but to have factory service performed if it is ever needed. The forearm nut (above, left), a variation of the complicated little monster from the 391 Urika, is not mentioned at all. One can hope that as now that much of its internals are plastic, no seizing would be likely to occur.

I personally find it hard to shake the feeling that the "perfect all around" shotgun is as elusive as ever. While I cannot possibly quibble with the all-load versatility prowess of the A400, for upland use an A400 with a 24 or 26 inch barrel would be the preferred configuration at least for me. If the notion was all day in the goose pit only, then yes-- a KO and a 30 inch barrel would likely be the more pleasing choice. The days of the affordable extra stock and extra barrel seem long gone, so that wouldn't be a particularly practical option for many folks.

The A400 is an extremely well-built gas-operated autoloader. Not quite as light, compact, or as soft-shooting in this configuration as has been suggested, the softest-shooting gas gun crown remains with the Maxus. The A400 comes up, swings, and points well, and is far easier on the eyes than the Xtrema2 that predates it or the plastic Maxus models that have been released thus far. It may not have the looks of a Urika 2 Gold, but it offers load versatility and robust construction that the Urika 2 lacks as high-intensity load shotgun. The relatively short (about 3/4 in.) and violent throw of its gas piston, before it bottoms out on the top of the magazine tube, gives plausibility to its fast cycle time. The rotating bolt and the KO3 innovation seem to keep the A400 bolt, action sleeve, and receiver lightly stressed; likely a very good thing if you're a 2-1/4 oz .of lead type of person and a good thing in general. At the end of all the shooting and patterning I'm left with a simple observation: the A400 is in general a good, dependable autoloader. It is both a bit over-priced and far too plasticy to satisfy many folks, though.

Copyright 2010 by Randy Wakeman. All Rights Reserved.

Custom Search